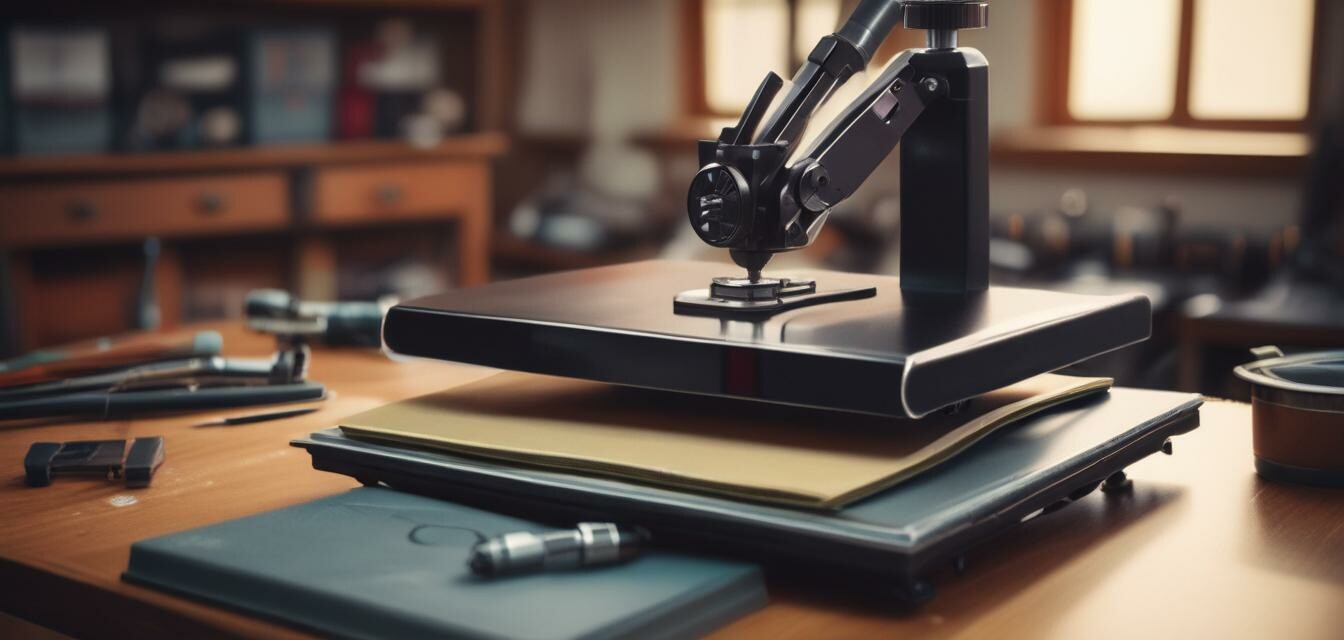

Advanced Heat Press Techniques

Are you an experienced heat press user looking to take your skills to the next level? Look no further! In this article, we'll dive into advanced heat press techniques to help you achieve professional results.

Key Takeaways

- Mastering heat press temperature and pressure control

- Using advanced materials and substrates

- Techniques for achieving precise registration and multicolor prints

- Optimizing heat press settings for specific fabric types

Temperature and Pressure Control

One of the most critical aspects of heat pressing is controlling temperature and pressure. Here are some advanced techniques to help you master this:

| Technique | Description | Benefits |

|---|---|---|

| Temperature profiling | Adjusting temperature during the heat press cycle to optimize results | Improved color vibrancy, reduced scorching |

| Pressure zoning | Applying different pressure levels to specific areas of the heat press | Enhanced image detail, reduced fabric distortion |

Advanced Materials and Substrates

Using advanced materials and substrates can take your heat press projects to the next level. Here are some options to consider:

- Digital heat presses for precise temperature control and versatility

- Multifunction heat presses for handling various fabric types and materials

- Specialty inks and coatings for unique effects and finishes

Precise Registration and Multicolor Prints

Achieving precise registration and multicolor prints requires skill and practice. Here are some advanced techniques to help you get started:

- Use a swing-away heat press for easy registration and precise alignment

- Utilize advanced software and design tools for precise color separation and registration

- Practice, practice, practice! Multicolor prints require patience and attention to detail

Optimizing Heat Press Settings

Optimizing heat press settings for specific fabric types is crucial for achieving professional results. Here are some tips:

| Fabric Type | Recommended Temperature | Recommended Pressure |

|---|---|---|

| Cotton | 300°F - 320°F | Medium - High |

| Polyester | 280°F - 300°F | Low - Medium |

| Blends | 290°F - 310°F | Medium |

Pros

- Advanced techniques for professional results

- Increased precision and control

- Ability to work with a wide range of materials and substrates

Cons

- Requires practice and patience to master

- May require additional investment in equipment and materials

- Can be time-consuming to achieve optimal results

Tips for Beginners

New to heat pressing? Start with the basics and work your way up to these advanced techniques. Remember to always follow safety guidelines and manufacturer instructions.